Background: Who cares about hanging chains?

Most people involved in creating gridshell structures care about hanging chains! They care because of the unique shape that a hanging chain makes - it is called a catenary, and it is important structurally because it represents a system in pure tension. This makes sense logically, because the chain is being pulled down by gravity at all points. This can be proven using calculus (infinite sum of small masses being pulled by gravity and by its neighbors - sounds like a FEA problem!), but its application greatly exceeds its creation.

|

| Hanging chain |

Uses of Catenary Shapes

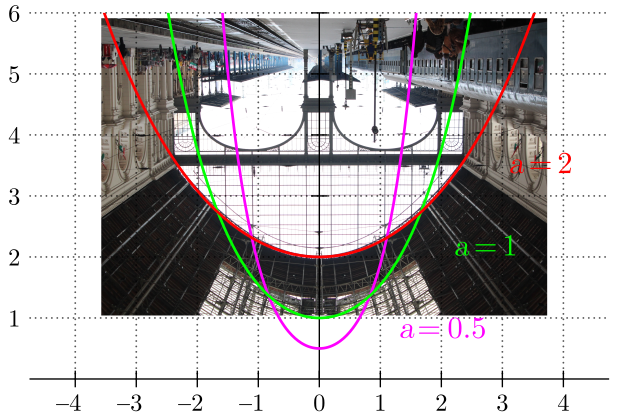

Catenary shapes are hanging systems in pure tension - but what would happen if you flipped one? Well, the chain would fall down and make another catenary. Now what if you solidify the chain, and then flip it? The result is a unique arch shape that is ideally in pure compression. This is used in architecture, such as the Keleti Railway Station in Budpaest, Hungary. When the upright photo is inverted and placed against a graph of a catenary curve, it matches very well, suggesting that the arch is indeed a catenary arch:

|

| Keleti Station in Budpaest, Hungary |

|

| Keleti Station in Budpaest, Hungary |

These catenary shapes can be applied to gridshell structures, essentially created from a lattice of hanging chains, that are then flipped and become the form of the gridshell structure.

Why Solidworks?

Solidworks has a Finite Element Analysis plugin, which we will be investigating to determine if it is robust enough for the research. We already know that Solidworks should be able to handle making a 3D model of a gridshell structure, and we know the simulation package can handle dynamic loads, which will be necessary for this research.

The first part of creating a hanging chain is designing and modeling a chain link; one that can be replicated and link into each other. Once the link is finished, the next step was to create a part to hold the hanging chain, so that the simulation can keep the holder fixed and apply a gravitational force to the chain links, creating the catenary shape. The chain link and chain holder part are:

|

| Chain Link |

|

| Chain Holder |

Once the parts were created, they were combined into an assembly. After the chain link was created (setting the number of links to adjust how far down the chain will hang), a Basic Motion Study was created, and gravitational force was added. When the motion study was run, the program produced a five-second video of the chain bouncing around, and when the video ended, the chain was hanging in what I presume to be a catenary shape, as shown below.

|

| Oblique view of hanging chain |

|

| Heads-on view of hanging chain |

Conclusion: Solidworks is Probably not the King of Catenaries

Solidworks was in fact able to handle a hanging chain, but there are a few limitations that probably sound the death knoll for Solidworks as a tool to decide the ideal shape for a gridshell. The first is the labor involved in creating the assembly. First, you have to create the chain link and the chain holder, then manually attach every chain link to each other. This would be prohibitively labor intensive for a longer chain, or a network of chains. Also, the computational resources involved in simulating even this basic chain were enough to strain my school laptop.

And even if doing a more complex hanging chain was feasible, it is still not clear whether it is possible to export the locations of the chain links, in order to make a model of the chain link. If it turns out to be possible to get some sort of printout of the chain link positions, I could spline along the points and create a curve, along which I could sweep a cross-section, thus creating an arch (or a network of arches to make a gridshell).

No comments:

Post a Comment